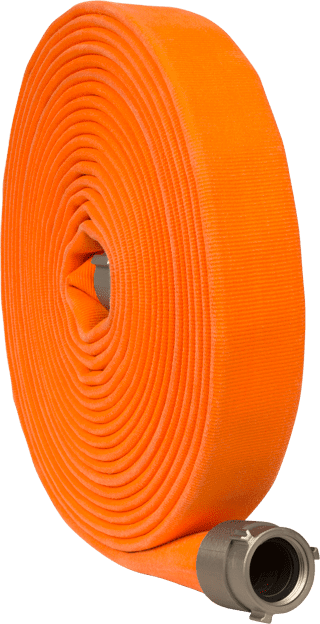

KEY HOSE – BIG-10

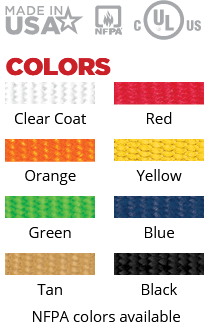

The standard in double jacket construction, combining 100% premium ring spun and filament polyester fibers over a heavy wall, ozone resistant, EPDM rubber liner. The outer jacket is mildew resistant and available with our iconic “Key-Lok” polyurethane based polymer impregnation for maximum abrasion and moisture resistance.

Description

Rugged, easy to handle and preferred by metro cities across the US and Canada — available in exclusive FDNY Spec with 1.88″ inside diameter and heavier construction with a 1-year all hazards warranty.

This reliable, double jacket fire hose is UL Listed*, tested to 600 and 800 psi and meets MIL-H-24606 latest edition for abrasion resistance.

Features a 10-year warranty and lifetime liner delamination guarantee.

Specifications:

| Item | Description | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FEATURES |

|

|||||||||||||||||||||||||||||||||||||||||||||||||

| SPECS |

*UL Listed

|

Specifications:

| Item | Description |

|---|---|

| WARRANTY INFORMATION |

Big-10 hose has a potential service life and warranty of 10 years with a lifetime warranty against liner delamination, barring mistreatment that would render it unfit for service. FDNY Spec hose also carries a 1-year all hazards warranty. Upon delivery, the hose shall be free from defects in materials and workmanship. DOWNLOAD SPEC SHEET |