KEY HOSE – MAGNUM/MAGLITE – NYLON DOUBLE JACKET HOSE

Unique double jacket construction, combining the supple high strength of Nylon 6.6 yarn and polyester filament fibers to form a highly abrasion resistant outer jacket and an inner jacket with increased tensile strength and durability. Our proprietary reverse twill weave construction reduces friction loss while ensuring the hose is lightweight, easy to handle and easy to pack.

Description

Customize the core of this double jacket attack line with your choice of a thin wall, high tensile, EPDM rubber liner (Magnum) or polyurethane liner (Maglite). Both of these dependable liner options provide superior kink resistance and eliminate ozone deterioration while maintaining the lightweight integrity of the hose.

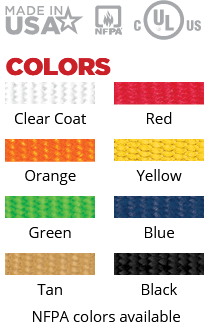

Maglite’s polyurethane liner material meets NSF (National Sanitation Foundation) Standard 61 for potable water. The outer jacket is mildew resistant and is also available with iconic “Key-Lok” polyurethane based polymer impregnation for additional abrasion and moisture resistance.

Specifications:

| Item | Description | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FEATURES |

|

|||||||||||||||||||||||||||||||||||||||||||||||||

| SPECIFICATIONS |

*Polyurethane liner not available

DOWNLOAD SPEC SHEET |

Specifications:

| Item | Description |

|---|---|

| WARRANTY INFORMATION |

Magnum hose with an EPDM liner has a potential service life and warranty of 10 years with a lifetime warranty against liner delamination, barring mistreatment that would render it unfit for service. Upon delivery, the hose shall be free from defects in materials and workmanship. Maglite hose with a polyurethane liner has a 5-year warranty against liner delamination, barring mistreatment that would render it unfit for service. Upon delivery, the hose shall be free from defects in materials and workmanship. |