Key Hose – Dura-Flow – Rubber Covered Attack

The lightweight, small diameter, rubber covered attack hose that packs a big punch. The heat and chemical resistant, nitrile/PVC through-the-weave design provides peak performance and maximum flow. With a test pressure of 600 psi, Dura‑Flow clearly outperforms conventional rubber covered attack lines.

Description

A rugged, thick ribbed outer jacket construction makes the hose highly resistant to kink, impact, punctures, cuts and abrasion.

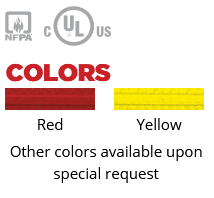

Ozone resistant, maintenance-free and no drying required, make Dura-Flow a reliable weapon in a firefighter’s arsenal. NFPA compliant and UL listed.

Specifications:

| Item | Description |

|---|---|

| FEATURES |

|

Specifications:

| Item | Description | ||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATIONS |

*UL Listed to 250 psi

|